According to IBM research, 77% of manufacturers say that computer vision and machine learning helps them meet their business goals. Indeed, computer vision and traditional machine vision play a crucial role in modern manufacturing processes.

Whether you want to read labels for quality assurance purposes, detect defects, detect the absence of products, or identify quality issues, computer vision can help solve your business problems. If an attribute is visible – for example, a defect, the presence or absence of an object – you can build a computer vision system to search for that attribute.

Enterprises around the world, across industries, depend on computer vision to solve problems. Car manufacturers use vision tools to identify defects, ensuring quality standards are met. Ice cream manufacturers use computer vision to detect when ice cream has melted on their assembly line, a costly problem.

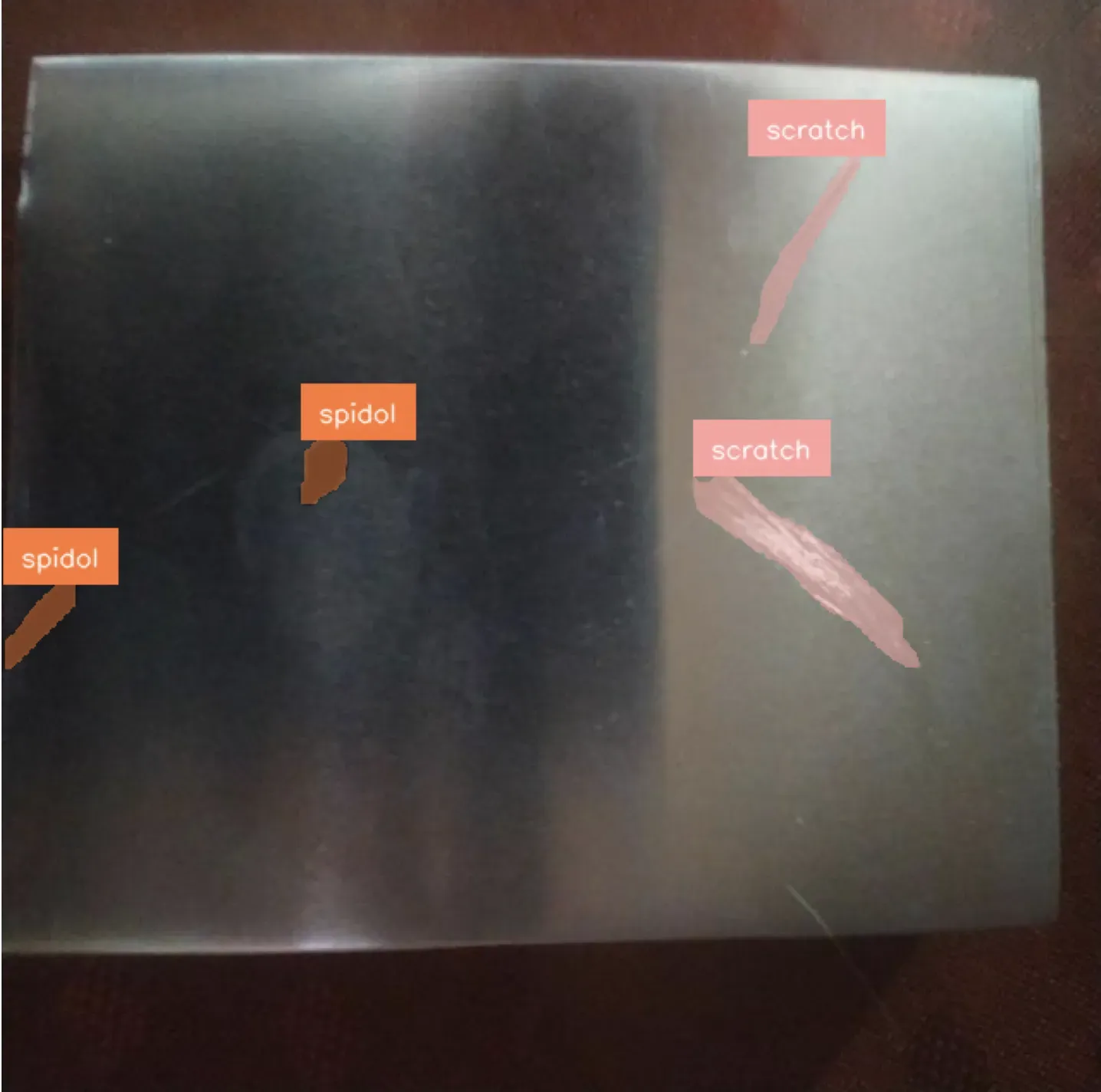

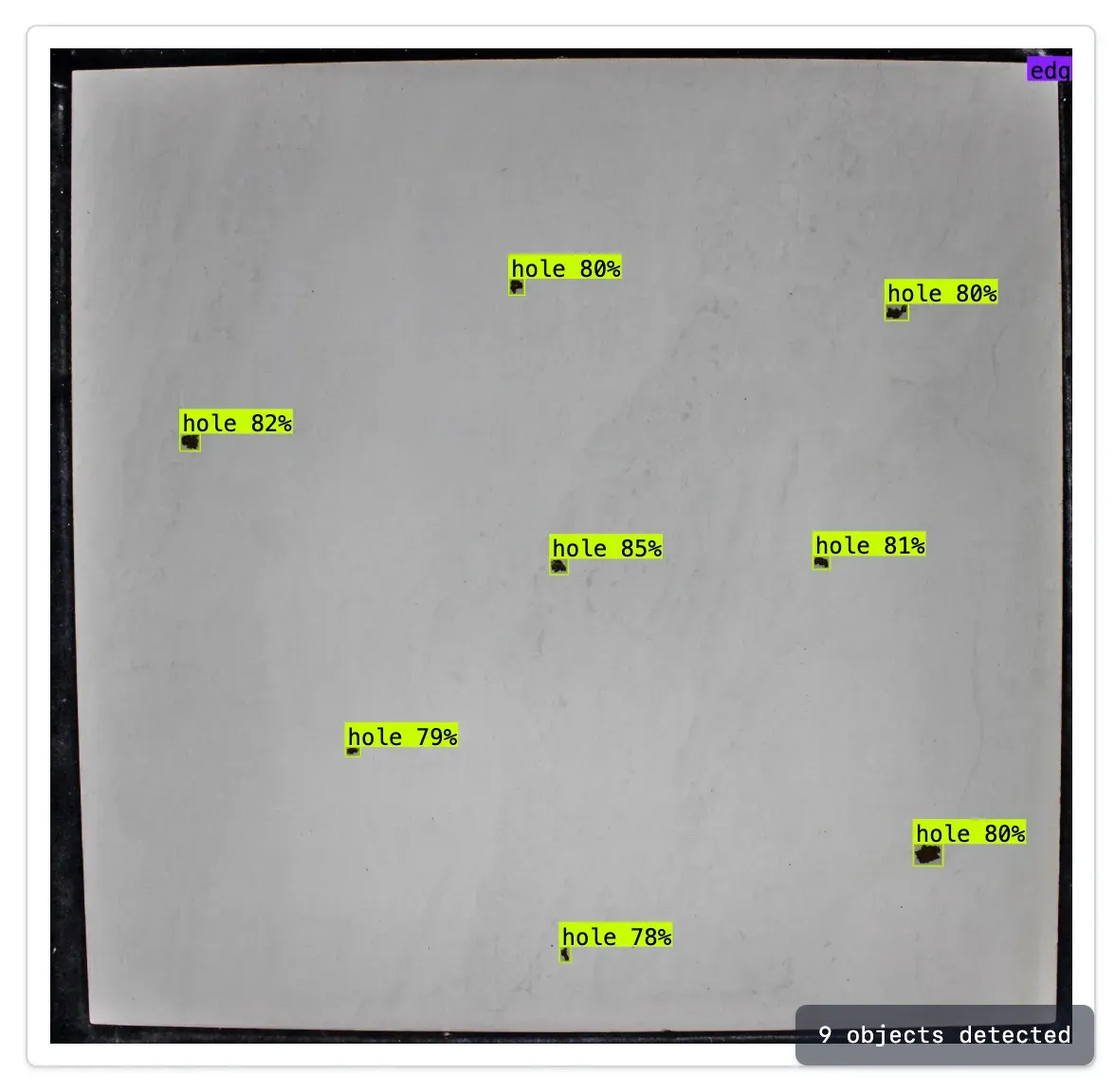

For example, here is a machine vision model being used to identify metal defects:

You may be wondering: how can you incorporate vision tools into your manufacturing systems? That is the question we are going to answer in this guide.

In this guide, we will discuss what computer vision is, how it compares to machine vision, and the computer vision-powered tools you can implement to solve business problems. We will end with guidance on how to get started building a system that meets your needs.

Without further ado, let’s get started!

What is Computer Vision?

Computer vision is a set of technologies that use visual inputs to solve problems. Computer vision systems typically use artificial intelligence. State-of-the-art AI systems are more capable than ever at tasks like identifying objects, segmenting regions in an object, identifying key points, and more.

You can use computer vision for many purposes, including to:

- Identify the presence or absence of objects or defects.

- Verify the color of an object.

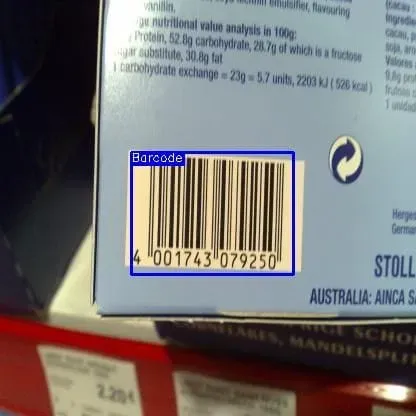

- Read barcodes, QR codes, ISBNs, and other identifiers.

- Read text on a package (i.e. a return label, a sell-by date).

- Verify the orientation of a product.

- Measure the dimensions of a product.

- Verify if an object is present in a particular region (i.e. if there are screws in all four corners of a product).

There are four main types of computer vision systems:

- Object detection: Detect the presence or absence of specific objects.

- Segmentation: Identify, to the pixel level, the location of an object in an image. Ideal for measuring objects.

- Classification: Assign one or more categories to an image.

- Keypoint detection: Identify key points on an image. Ideal for checking the orientation of a product.

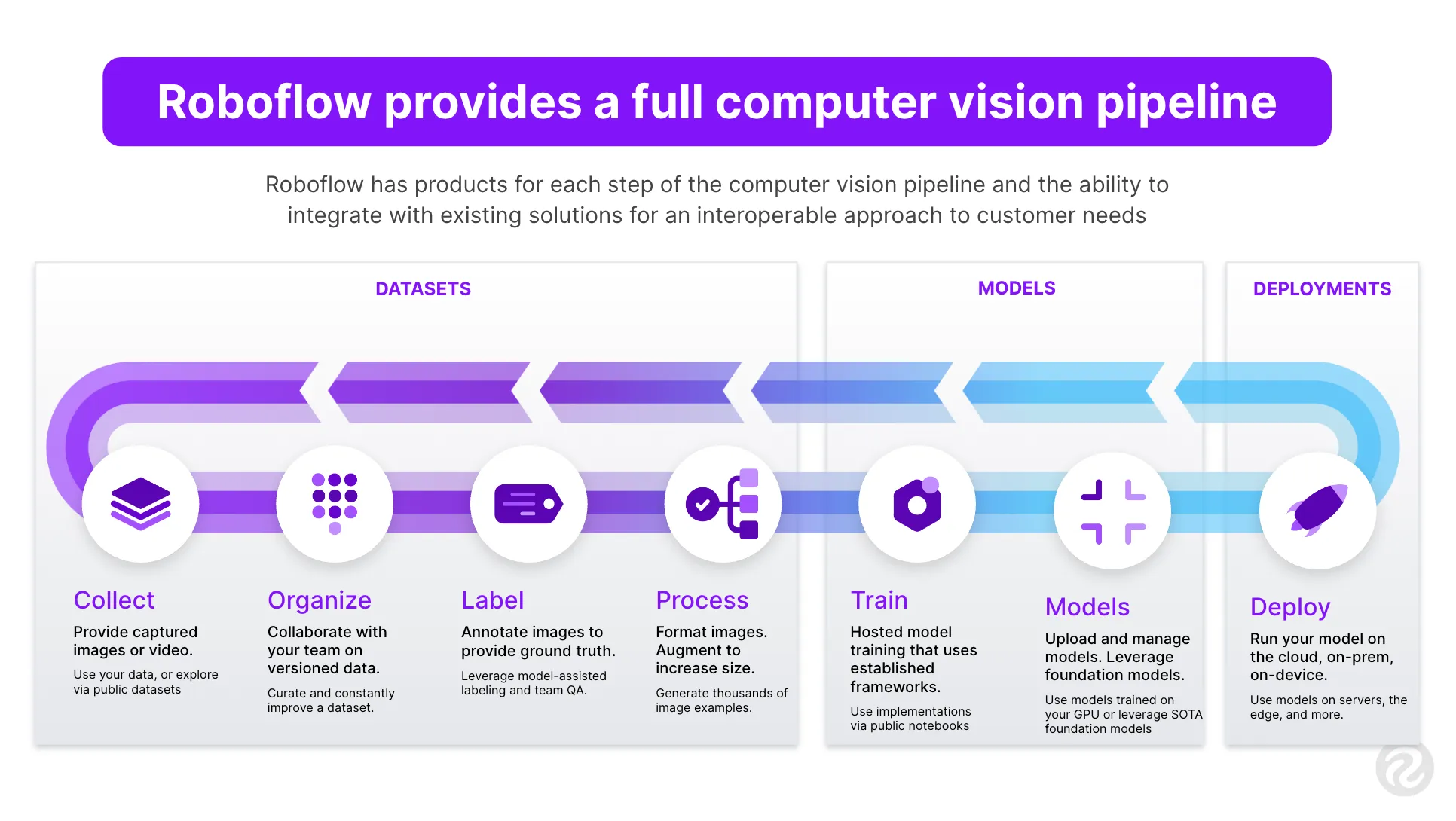

To integrate a computer vision system into your manufacturing processes, you need a model that can identify objects of interest. This model can be tuned to identify specific objects and can be trained in an afternoon. By using your business data to train a model, you can build a system that attains greater accuracy than any pre-made system.

Once you have a model, you can integrate it directly into your manufacturing pipelines. Using an open source tool, like Roboflow Inference, you can run your model on camera feeds or RTSP streams in a factory. You can write custom logic that triggers an action when a particular condition is met. For example, if a defect is detected in a product, that product could be flagged in real-time and moved out of the assembly line.

Computer Vision vs. Machine Vision

Machine vision, also referred to as “rules-based” vision, has been solving problems in manufacturing for decades. Machine vision refers to rules-based algorithms that are written to solve specific problems like detecting edges or reading barcodes.

Machine vision systems can solve problems like:

- Detecting edges.

- Reading text.

- Bead inspection.

- Measuring edges.

- Pattern matching.

For these use cases, machine vision can be effective. With that said, computer vision opens many opportunities, allowing you to perform both basic and complex tasks, agnostic to hardware, and in a way that is adaptable to new environments and processes.

It’s possible to use a combination of both machine vision and computer vision in a facility. Installed machine vision systems, such as barcode readers, could be used alongside computer vision systems used to check that a product is free from specific defects or is oriented correctly.

Computer vision systems can be deployed on computers like NVIDIA Jetsons or Raspberry Pis, which are typically cheaper than purpose-built machine vision systems.

Integrating Computer Vision Tools Into an Assembly Line

Computer vision tools can help increase efficiency, reduce defect rates, ensure compliance, and more. Once a use case for computer vision is identified, the next step is to integrate computer vision systems into an assembly line or manufacturing process.

You can use a tool like Roboflow to build a system that meets your requirements. Roboflow offers the tools you need to create a vision system unique to your business. The following is a simplified overview of how to build such a system.

First, you need to collect data representative of your use case. For example, you might collect images of glass for a glass inspection system. You can then label objects of interest in your data – products, scratches, cracks, chips, or anything else. These labels can be used to train a purpose-built model for your use case.

With a custom model, you can deploy it anywhere in your facility. This process involves identifying hardware on which you can run your models or using devices with internet connection.

The NVIDIA Jetson is a common choice for running models in manufacturing settings. Then, you will need a camera. Your camera does not need to have vision capabilities, but should offer an Ethernet or USB connection and support the image quality required to identify your objects of interest. You can combine your camera with your vision hardware to start running your model.

Once you have a model in production, you can work toward improving it. For example, your system might identify 95% of cracks in glass, but struggle with edge defects. You could collect more data in real time using active learning, a feature built into the Roboflow Inference deployment solution. This data can then be fed back in to train a new version of your model that is more accurate.

Conclusion

Vision tools – computer and machine vision – are a cornerstone of modern manufacturing processes.

You can combine machine vision systems with computer vision to build more powerful systems. For example, you can train a computer vision system to identify defects you notice in your assembly line; you can build a system that checks the orientation of a product.

Computer vision and machine vision allow you to reduce defect rates, ensure stability in your assembly line, and enforce robust quality checks for your products.

In this guide, we discussed what computer and machine vision are, the problems you can solve with each method, and how you can use computer vision to solve business problems.

If you think computer vision can solve your business problems, contact the Roboflow sales team. Our sales team are experts in developing custom computer vision solutions for use cases across industry, from logistics to manufacturing to analytics.